Drawbar Trailers Buying Guide

Drawbar trailers are a type of transportation solution which involves coupling one or several trailers to a towing vehicle via a drawbar. The drawbar connects the towing vehicle to the trailer at a single pivot point, allowing the trailer to move freely behind the vehicle on rough or uneven surfaces. The coupling system ensures a strong connection between the vehicles without limiting mobility.

What do Drawbar Trailers do?

Drawbar trailers serve numerous purposes and add versatility to the transportation industry. Here are some of their most notable functions:

Increasing load capacity: By coupling one or more drawbar trailers to a towing vehicle, the load capacity can be vastly increased without the need for additional vehicles. This helps to improve transportation efficiency, reduce fuel consumption, and lower overall costs.

Flexible transportation options: Drawbar trailers can accommodate various cargo types, from pallets and containers to heavy equipment and machinery. This makes them suitable for a wide range of industries, including manufacturing, construction, and agriculture.

Improved maneuverability: Due to the pivot point of the drawbar coupling, these trailers offer improved maneuverability compared to larger articulated trucks or semi-trailers. This makes drawbar trailers ideal for applications in tight spaces or difficult terrain.

Easy coupling and uncoupling: The drawbar coupling system allows for quick and easy attachment or detachment of the trailer from the towing vehicle, enabling the driver to switch between different configurations, as required by the transportation task at hand.

Why Are Drawbar Trailers So Important?

Drawbar trailers play a significant role in the transportation industry for various reasons. Here are some of the key factors that contribute to their importance:

Enhanced Efficiency: Drawbar trailers offer a convenient solution to increase haulage capacity and transport larger volumes of goods with a single vehicle, ultimately optimizing efficiency and reducing transportation costs.

Versatility: The adaptability of drawbar trailers to diverse cargo types, industries, and terrains makes them indispensable for commercial and industrial operations. This flexibility allows businesses to meet their transportation needs effectively and with reduced logistical challenges.

Environmental Benefits: With the potential to carry more cargo with fewer vehicles, drawbar trailers contribute to lower fuel consumption and emissions, which in turn helps to minimize the environmental impact associated with transportation.

In conclusion, drawbar trailers are an essential component of the modern transportation industry due to their adaptability, efficiency, and environmental benefits. Their widespread use spans various sectors and industries, driving economic growth and contributing to more sustainable practices in goods transportation.

How to Maintain Drawbar Trailers

Drawbar trailers are a popular type of trailer used in the transportation industry for hauling heavy loads. Proper maintenance of these trailers is essential to ensure their longevity, efficiency, and safety. This article will walk you through some crucial maintenance tips for your drawbar trailers.

Regular Inspection

Performing regular inspections is the first step in maintaining your drawbar trailer. Routinely check for any signs of damage, corrosion, or wear and tear in the following areas:

Tires and wheels

Brake system

Suspension components

Electrical systems and lighting

Coupling devices

Keep a maintenance log and record the dates of inspections to ensure consistent oversight.

Lubrication

To keep your drawbar trailer in good working condition, lubricate all moving parts, including:

Kingpins

Coupling devices

Joints and pivot points

Regular lubrication reduces friction and prevents premature wear, ultimately prolonging the life of your trailer.

Tire Maintenance

Tire maintenance is crucial to avoid accidents caused by blowouts or tire failures. Check your drawbar trailer’s tires for proper inflation, uneven wear, cuts, or embedded objects. Also, monitor tread depth, and replace tires when necessary.

Brake System

Your drawbar trailer’s brake system is vital for safety. Periodically check and adjust the brake slack, and replace worn friction linings when needed. Inspect the brake hoses and lines for cracks, chafing, or leaks, and check the brake fluid reservoir to keep it at the right level.

Electrical System

Ensure all lights and electrical connections are working correctly to avoid accidents or legal issues. Check the lighting system, including brake lights, turn signals, and clearance lights, and replace any burnt-out bulbs.

Clean and Protect

Regularly clean your drawbar trailer to remove accumulation of dirt, grease, or debris that can lead to corrosion or component failure. Protect the metal surfaces with anti-corrosion sprays or coatings, and repaint the trailer when needed to keep it in good condition.

Load Distribution

Proper load distribution is key to safety and maintaining the trailer’s structural integrity. Make sure loads are evenly distributed, and do not exceed the trailer’s weight rating.

Professional Assistance

Lastly, consider consulting with a professional service technician for regular maintenance checks or when issues arise that are beyond your expertise. Ensuring your trailer receives professional attention will provide peace of mind and help maintain its value.

By following these maintenance tips, you can keep your drawbar trailer in peak condition and ensure its safe and effective operation for years to come.

Sales and Prices of Different Types of Drawbar Trailers

The drawbar trailer industry has seen significant growth in recent years as businesses continually look for ways to boost productivity, reduce transportation costs, and enhance efficiency. Drawbar trailers are versatile vehicles designed to transport goods, making them essential in various industries like construction, logistics, and agriculture. Different types of drawbar trailers cater to specific transportation requirements, and prices vary depending on the trailer's features, capacity, and materials used. This article offers an overview on the sales and prices of different drawbar trailers.

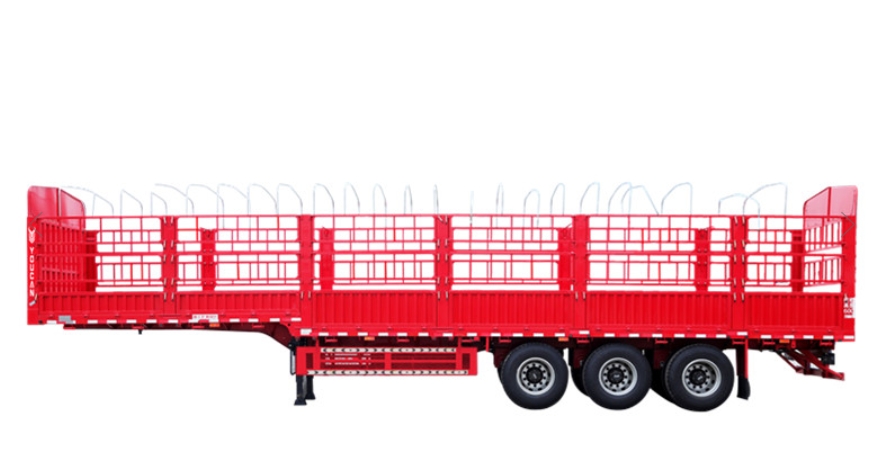

Flatbed Drawbar Trailers

Flatbed drawbar trailers are the most common type, featuring a flat and open deck without sidewalls or a roof. Primarily used for transporting large, heavy, or irregularly shaped items, they are popular in the construction and heavy machinery industries.

Sales trends: Flatbed drawbar trailers are consistently high in demand due to their versatility and affordability, thus leading to strong sales figures.

Prices: Prices vary based on dimensions, materials, and additional features; the cost generally ranges between 50,000 to 30,000.

Box Drawbar Trailers

Box drawbar trailers, also called closed trailers, are covered trailers that offer protection against external elements. They are primarily used for transporting goods sensitive to weather conditions, such as food, clothing, and electronics.

Sales trends: Box drawbar trailers have rising sales in industries like e-commerce, perishable goods transportation, and pharmaceuticals due to their ability to protect cargo from damage.

Prices: Prices largely depend on size, materials, and insulation, ranging between 10,00 to 50,000.

Low Loader Drawbar Trailers

Low loader drawbar trailers, or low-bed trailers, have a lower ground clearance and a loading deck that is closer to the ground. Designed for heavy transportation, they are preferred for carrying oversized or heavy equipment.

Sales trends: As the construction and mining industries continue to grow, low loader drawbar trailers have experienced a steady increase in sales.

Prices: Prices vary due to customization, size, and materials used, typically ranging from 20,00 to 80,000.

Refrigerated Drawbar Trailers

Refrigerated drawbar trailers are equipped with a temperature-control system to transport temperature-sensitive goods, such as fruits, vegetables, and frozen products.

Sales trends: The growth of the cold chain market is driving sales for refrigerated drawbar trailers, with food and pharmaceutical sectors being major consumers.

Prices: Refrigerated drawbar trailer prices mostly depend on the cooling system, insulation, and size, ranging between20,000 and 100,000.

Curtainsider Drawbar Trailers

Curtainsider drawbar trailers feature adjustable PVC curtains along the sides, allowing easy loading and unloading of goods while providing protection during transportation. They are widely used for retail and consumer goods distribution.

Sales trends: The curtainsider drawbar trailers have maintained stable sales due to their efficient loading and unloading capabilities and flexibility in serving various industries.

Prices: Prices for curtainsider drawbar trailers are based on size, material quality, and curtain systems, with prices ranging between 15,000 and 60,000.

In conclusion, drawbar trailers are an essential component in numerous industries, catering to various transportation requirements. The sales and prices of different types of drawbar trailers depend on factors like materials, size, features, and industry needs. As transportation demands continue to evolve, we can expect further innovations in drawbar trailer designs and functionalities, catering to an even broader range of applications.

Drawbar Trailers Common Technical Troubleshooting FAQs

Q1:What are the common technical issues with drawbar trailers?

A1:The common technical issues with drawbar trailers include uneven tire wear, braking system problems, lighting issues, and hitch connection problems.

Q2:How can I resolve uneven tire wear?

A2:To resolve uneven tire wear, ensure proper tire inflation, alignment, and balance. Regularly inspect and rotate the tires, and replace them if the wear is severe.

Q3:Braking problems, what should I check?

A3:For braking problems, check the brake assemblies, brake fluid levels, air pressure (if air brakes), brake lines, and brake controller. Perform regular maintenance and replace any worn parts.

Q4:What about lighting issues?

A4:For lighting issues, inspect bulbs, wiring, connectors, and fuses. Ensure all connections are clean and secured tightly. Replace any damaged or malfunctioning components.

Q5:How to solve hitch connection problems?

A5:Solve hitch connection problems by checking the hitch, safety chains, and locking mechanism. Clean and lubricate the connections, adjust the hitch height, and inspect for any wear or damage. Replace any/components if necessary.

Suppliers of Drawbar Trailers

The Youcan trailer was established in 1999 and has rich experience in Interlink Trailers production and provides complete Interlink Trailers solutions for different applications. The company has 23 years of experience and specializes in providing aluminum tank trucks, fuel tank trucks, bulk cement tank trucks, dump trailers, tipper trailers, pile/sidewall trailers, flatbed trailers, low bed trailers, container transport trailers, cargo trailers, interlock trailers and hundreds of other products.

Welcome to contact us to get the latest price of new semi-trailers. Competitive price, reliable quality, waiting for you to buy!

WhatsApp

WhatsApp

sales@youcantrailer.com

sales@youcantrailer.com

+8615203709888

+8615203709888