Comparison of ten common Trailers

A trailer is a non-motorized vehicle designed to be towed by a powered vehicle, such as a truck, car, or tractor. Trailers come in various sizes, shapes, and types, each serving a specific purpose in transporting goods, materials, or equipment. They usually have a chassis, a set of wheels, a coupling device for attaching them to the towing vehicle, and a loading/distribution system to support the cargo.

Trailers are widely used in transportation, logistics, agriculture, and various other industries, providing a flexible and efficient means of moving goods from one place to another. Depending on the type of cargo being transported, specific trailer types have been developed, such as flatbed, low bed, dry van, tanker, or refrigerated trailers, among others. Each type of trailer is designed to address specific transportation requirements, making it essential to select the most appropriate trailer for your specific needs.

Below we will introduce the 10 most common trailer types and make a detailed comparison of their advantages and disadvantages to provide you with a reference for choosing the most suitable trailer.

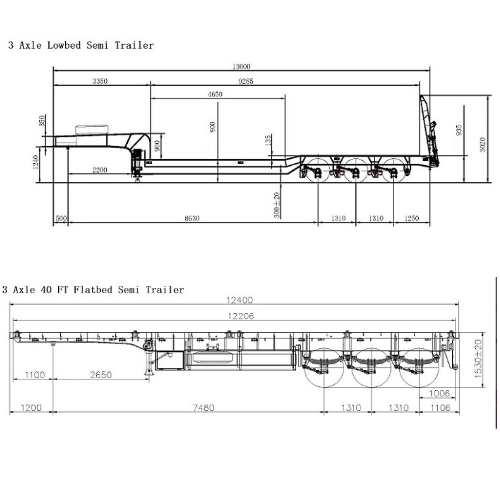

Flatbed Semi Trailer

What is a Flatbed Semi Trailer?

A flatbed semi trailer is a type of transportation equipment characterized by its open, level platform without sides or a roof. This design allows for easy loading and unloading of various types of goods, materials, and cargo, offering versatility and ease of access to loads. Flatbed semi trailers are frequently used across multiple industries for the transportation of a wide range of items, from construction materials to agricultural equipment and vehicles.

Advantages of the Flatbed Semi Trailer:

Versatility: Flatbed semi trailers are suitable for transporting a wide variety of cargo, including construction materials, machinery, vehicles, and more. Their open design enables them to accommodate loads with irregular shapes and sizes.

Easy loading and unloading: The open platform allows for quick and efficient loading and unloading from all sides, making it convenient for various types of cargo handling equipment like forklifts and cranes.

Durable construction: Flatbed semi trailers are usually built with robust materials, such as steel or aluminum, ensuring the trailer can withstand heavy loads and harsh operating conditions.

Adaptability: These trailers come in various sizes and load capacities, making it easier to find a suitable trailer for specific transportation needs.

Disadvantages of Flatbed Semi Trailer:

Lack of cargo protection: Due to their open design, flatbed semi trailers do not provide built-in protection from weather elements, dirt, or damage. Therefore, additional precautions, such as tarps or straps, may be necessary to protect cargo during transportation.

Load securement: It is essential to have proper load securement measures in place to prevent cargo movement or loss during transit. This may require additional effort, equipment, and time to ensure the cargo is safely secured on the trailer.

Risk of cargo theft: The open nature of flatbed semi trailers may make the cargo more susceptible to theft, especially during overnight stops or long layovers.

By carefully considering the advantages and disadvantages of flatbed semi trailers, you can make an informed decision about whether a flatbed semi trailer is the right choice for your specific transportation needs.YOUCAN can provide you with professional Flatbed Semi Trailer solutions and the best Flatbed Semi Trailer price.

Low Bed (Lowboy) Trailer

What is Low Bed (Lowboy) Trailer?

A low bed (lowboy) trailer is a type of trailer specifically designed to transport tall and heavy cargo, featuring a lower deck height than other types of trailers. The lowered deck height and high load capacity make these trailers well-suited for transporting construction machinery, industrial equipment, and other oversized or heavy items. Lowbed Semi Trailer can come in various configurations, including fixed neck, detachable gooseneck, and hydraulic ramps that aid in loading and unloading.

Lowbed Semi Trailer

Advantages of the Low Bed (Lowboy) Trailer:

Lower deck height: The lower deck height accommodates taller cargo, adhering to height restrictions on roads and bridges while offering a lower center of gravity, which enhances stability during transportation.

High load capacity: Low bed trailers can handle significant weight, making them ideal for heavy machinery and equipment transportation.

Ease of loading and unloading: The low deck design and detachable necks or hydraulic ramps on some models simplify the loading and unloading process, particularly for heavy-duty equipment.

Versatility: Low bed trailers can carry different types and sizes of cargo, including irregularly shaped items, and can be adapted with extensions or extra axles to accommodate unique loads.

Improved safety: By allowing taller cargo, low bed trailers help prevent potential accidents related to exceeding height restrictions.

Disadvantages of Low Bed (Lowboy) Trailer:

Limited cargo types: Although versatile, low bed trailers are not suitable for all cargo types, particularly palletized or smaller items that could be better accommodated by other trailer styles, such as dry vans or flatbeds.

Higher cost: Low bed trailers can be more expensive to purchase, maintain, and insure due to their specialized design and increased load capacity.

Reduced maneuverability: Due to their size and construction, low bed trailers can be challenging to maneuver in tight spaces or on narrow roads, compared to other trailer types.

Legal restrictions: Depending on the cargo, route, and jurisdiction, low bed trailers might be subject to additional permits or weight and size restrictions, potentially increasing transportation costs and extending transit times due to added planning considerations.

In summary, low bed (lowboy) trailers offer unique advantages for transporting tall and heavy cargo, but they also have some limitations. It's essential to evaluate your specific transportation requirements to determine if a low bed trailer is the most suitable option.YOUCAN can provide you with professional low bed (lowboy) trailer solutions and the best low bed (lowboy) trailer price.

Dry Van Trailer

What is Dry Van Trailer?

A Dry Van Trailer is an enclosed trailer designed to protect goods from weather, dirt, and damage during transportation. It is the most common type of trailer used for carrying general goods, consumer products, and non-perishable items. These trailers typically have a rectangular box-shaped structure mounted on a chassis with wheels and are commonly seen connected to a semi-truck.

Advantages of the Dry Van Trailer

Protection: The enclosed structure protects goods inside from weather elements such as rain, snow, or sunlight, ensuring cargo arrives in good condition.

Security: A dry van trailer helps prevent theft or vandalism, as the cargo is locked inside the enclosed container, keeping it out of sight and secure.

Versatility: Dry van trailers can accommodate various cargo types, from palletized goods to boxed or containerized products, making them suitable for a wide range of industries.

Easy Loading and Unloading: Most dry van trailers come with rear doors, and many also have side doors, enabling efficient loading and unloading using a forklift or pallet jack.

Availability: Due to their popularity, dry van trailers are widely available for purchase or rent, making them a readily accessible transportation option.

Disadvantages of Dry Van Trailer

Limited Cargo Types: Dry van trailers are not suitable for carrying perishable goods that require temperature control, oversized cargo that may exceed height or width limitations, or hazardous materials that need specialized containers.

No Temperature Control: These trailers lack temperature control systems, making them ill-suited for temperature-sensitive or perishable goods, which would require a refrigerated (reefer) trailer instead.

Reliance on Loading Docks: Most dry van trailers are designed to be loaded and unloaded at a dock with a raised platform. This can limit their use in locations without proper loading facilities.

Cargo Weight Limit: Though dry van trailers can carry various types of cargo, there is a limit to the maximum weight they can accommodate. Overloading can lead to structural damage, decreased fuel efficiency, or potential fines and penalties.

Selecting the appropriate trailer type for your specific transportation needs is vital. The strengths and limitations of dry van trailers must be weighed against your cargo requirements to make the most suitable and efficient decision.

Refrigerated (Reefer) Trailer

What is Refrigerated (Reefer) Trailer?

A Refrigerated (Reefer) Trailer is a specialized type of enclosed trailer designed to transport perishable goods, such as food, pharmaceuticals, and other temperature-sensitive products. These trailers are equipped with a temperature-control system that maintains a consistent temperature inside the trailer, preserving the quality of the cargo.

Advantages of the Refrigerated (Reefer) Trailer:

Temperature control: Reefer trailers maintain a specific temperature throughout the journey, ensuring that perishable goods remain fresh and unspoiled, even over long distances.

Protection from environmental factors: The enclosed design safeguards the cargo from external weather conditions, dust, and damage that might occur during transportation.

Versatility: Refrigerated trailers can transport a wide range of temperature-sensitive products, including frozen items, fresh produce, and pharmaceuticals.

Regulatory compliance: Reefer trailers help businesses comply with food safety and pharmaceutical transportation regulations by providing the necessary environment for preserving the cargo's quality.

Increased demand: The increasing demand for fresh and frozen goods worldwide makes refrigerated trailers an essential component of modern distribution networks.

Disadvantages of Refrigerated (Reefer) Trailer:

Higher initial cost: Due to the need for insulation and temperature-control systems, reefer trailers tend to be more expensive compared to regular dry van trailers.

Increased operating expenses: The refrigeration unit requires fuel to operate, increasing fuel consumption and raising the operating costs during transportation.

Maintenance requirements: Proper maintenance of the refrigeration unit, including regular inspections and any necessary repairs, is essential for optimal performance, which can lead to additional costs.

Limited cargo options: Due to the temperature control and insulation, reefer trailers are not suitable for transporting cargo that requires ventilation or does not need a temperature-controlled environment.

Choosing a refrigerated trailer depends on the specific transportation needs of your cargo. While they offer significant advantages for temperature-sensitive goods, the higher cost and maintenance needs of reefer trailers must be considered when making a decision.

Extendable Trailers

What is Extendable Trailers?

Extendable trailers, also known as extendable or telescopic flatbed trailers, are specialized trailers designed to carry oversized and elongated cargo. These trailers can be adjusted in length to accommodate the specific transportation needs of loads such as long steel beams, wind turbine blades, bridge components, or modular housing units.

Advantages of the Extendable Trailers:

Versatility: Extendable trailers can be used for a wide range of elongated and oversized cargo, making them a flexible and adaptable solution for various industries and transportation needs.

Efficient Cargo Handling: The adjustable length feature allows transportation professionals to handle oversized loads more efficiently, reducing the need for multiple smaller trailers or complex arrangements.

Safety: By providing an appropriate platform for elongated cargo, extendable trailers help maintain proper load distribution, reducing the risk of accidents and ensuring cargo safety.

Time-saving: Extendable trailers enable transportation companies to quickly and easily adjust the trailer length to fit the cargo, minimizing downtime and streamlining the entire loading and unloading process.

Disadvantages of Extendable Trailers:

Higher Initial Cost: Compared to standard trailers, extendable trailers may have a higher initial cost due to their specialized design and additional mechanical components.

Increased Maintenance: The extendable and telescopic components may require more frequent inspections and maintenance to ensure proper functioning and safety during use.

Limited Availability: Extendable trailers may not be as widely available or as accessible as other, more common trailer types. This may result in potential challenges when sourcing or renting an extendable trailer.

Permit Requirements: Transporting oversized loads may necessitate obtaining special permits or escorts depending on the cargo dimensions and local transportation regulations. This can potentially add complexity to the planning and execution of transportation projects.

By carefully weighing the advantages and disadvantages of extendable trailers, you can determine whether they are the best solution for your specific transportation needs.

Tanker Trailers

What is Tanker Trailers?

Tanker trailers are specialized trailers designed for the transportation of liquids, gases, or dry bulk materials. They come in various shapes, sizes, and materials, depending on the specific cargo they carry, such as chemicals, fuel, water, or food-grade liquids. Tanker trailers are equipped with necessary valves, pumps, and discharge systems to load and unload the cargo efficiently and securely.

Advantages of Tanker Trailers:

High hauling capacity: Tanker trailers are capable of carrying large quantities of liquids or bulk materials, making them ideal for large-scale transportation requirements.

Safety features: These trailers are designed with appropriate safety features such as baffles, pressure relief valves, and containment chambers to minimize the risks associated with transporting potentially hazardous materials.

Customization: Tanker trailers can be tailored to meet specific industry requirements, from food-grade stainless steel tanks for milk or juice transportation to insulated trailers for temperature-sensitive materials.

Efficient loading and unloading: The specialized loading and unloading systems of tanker trailers optimize the transfer process, reducing handling time and the risk of spills or leaks.

Disadvantages of Tanker Trailers:

Limited cargo options: Tanker trailers are specially designed for liquids, gases, or bulk materials, making them unsuitable for transporting other types of cargo, such as palletized goods or equipment.

Residual cargo and cleaning: Certain materials may leave residues inside the tanker, which requires thorough cleaning before the trailer can be used to transport different cargo, increasing downtime and maintenance costs.

Potential environmental hazards: In the event of an accident or leakage, tanker trailers carrying hazardous materials can pose significant environmental risks and require strict adherence to safety procedures and regulatory compliance.

Specialized equipment and training: Many tanker trailers require specific equipment or expertise to effectively and safely load, unload, and transport the cargo, necessitating specialized training for drivers and handlers.

Side Wall Trailers

What is Side Wall Trailers?

A Side Wall Trailer is a variant of a flatbed trailer that features sidewalls on its platform to provide better support and security for cargo during transit. They are particularly useful for transporting goods that require additional lateral stability and protection, such as pallets, containers, or bulky equipment.

Advantages of Side Wall Trailers:

Enhanced cargo support: The sidewalls provide better support for the loads, reducing the potential for cargo shifts during transit and making the trailer more stable on the road.

Increased cargo protection: The sidewalls offer added protection from road debris or adverse weather conditions, helping to keep the cargo clean and safe from potential damage.

Flexible loading: Side Wall Trailers retain the benefits of a flatbed trailer, allowing for easy loading and unloading of cargo from the top, rear, or sides.

Improved cargo organization: The sidewalls make it easier to organize and stack cargo securely, increasing carrying capacity and optimizing space utilization.

Disadvantages of Side Wall Trailers:

Added weight: The sidewalls can increase the total weight of the trailer, which may decrease fuel efficiency and affect payload capacity.

Potential limitations for certain cargo types: While maintaining flatbed trailer flexibility, the sidewalls could still present limitations for certain oversized or irregularly-shaped cargo that would not fit within the sidewalls.

Maintenance: The sidewalls may require additional maintenance work or repair in case of wear or damage.

Reduced visibility: The presence of sidewalls could hinder visibility for the driver while loading, unloading, or maneuvering the trailer in tight spaces.

Overall, Side Wall Trailers have unique advantages and disadvantages that make them suitable for specific transportation needs. It's essential to assess your cargo's characteristics and requirements to determine if a Side Wall Trailer is the appropriate choice for your situation.

Curtain-Sided Trailers

What is Curtain-Sided Trailers?

Curtain-sided trailers are a type of semi-trailer with a flexible, retractable tarpaulin (often called a curtain) covering the sides, which can be easily slid back to allow access to the cargo from both sides. They have a rigid roof and are used for transporting goods that require protection from the elements but also need accessibility during loading and unloading.

Advantages of Curtain-Sided Trailers:

Ease of loading and unloading: The retractable curtains allow for easy access from both sides of the trailer, simplifying the process of loading and unloading cargo.

Efficient use of time: The sliding curtains enable faster loading and unloading, reducing wait times and increasing operational efficiency.

Weather protection: The curtains provide protection against weather elements such as rain, wind, and dust, helping to keep cargo in good condition during transport.

Versatility: Curtain-sided trailers can carry a wide range of goods, including palletized items, boxes, and other bulky cargo, making them suitable for various industries and transportation requirements.

Enhanced security: Most curtain-sided trailers come with locking systems that secure the curtains in place, limiting unauthorized access to the cargo.

Disadvantages of Curtain-Sided Trailers:

Limited structural support: Unlike fully enclosed trailers, curtain-sided trailers may offer less structural rigidity due to the flexible nature of the tarpaulin sides, potentially making them unsuitable for highly delicate or fragile cargo.

Less insulation: The tarpaulin sides offer limited insulation compared to solid walls, making curtain-sided trailers unsuitable for temperature-sensitive items, such as perishable goods or some pharmaceutical products.

Potential for damage: Although the curtains protect the cargo from direct exposure to weather conditions, they may not provide the same level of protection as a rigid, fully enclosed trailer, and could potentially be damaged during transport.

Security concerns: While curtain-sided trailers do provide some security measures, they may not be as secure as a fully enclosed trailer due to the nature of the curtain material, which may be more easily breached.

Curtain-sided trailers offer several advantages, including ease of access and weather protection, but they may not be the ideal choice for every transportation scenario. It is essential to consider your specific cargo requirements, security concerns, and other factors when choosing the most appropriate trailer type.

Car Carrier (Auto Transport) Trailers

What is Car Carrier (Auto Transport) Trailers

Car Carrier (Auto Transport) Trailers are specialized transportation equipment designed specifically for hauling vehicles, such as cars, trucks, and motorcycles. These trailers come in different configurations, including single-vehicle and multi-vehicle carriers, with various ramps and tie-down systems to secure the vehicles during transportation.

Advantages of Car Carrier (Auto Transport) Trailers:

Efficient vehicle transportation: Car carriers enable the efficient and safe transportation of multiple vehicles simultaneously, saving time and resources compared to individually transporting each vehicle.

Secure and stable: The specialized ramps and tie-down systems used in auto transport trailers ensure that the vehicles are securely and safely held in place during transit, reducing the risk of damage.

Customization for different vehicles: Car carriers can be designed to accommodate a wide range of vehicle types and sizes, catering to various transportation needs in the auto industry.

Reduced wear and tear on transported vehicles: By transporting the vehicles on a trailer, there is no additional mileage accrued on the vehicles themselves, resulting in reduced wear and tear and preserved value.

Suitable for long-distance transportation: Car carriers offer a reliable solution for long-distance vehicle transportation that might be unsuitable for driving due to safety, fuel economy, or specific vehicle limitations.

Disadvantages of Car Carrier (Auto Transport) Trailers:

Size and maneuverability: Due to their large size, car carriers can be challenging to maneuver, particularly in urban environments with tight spaces and parking restrictions.

Higher cost: Auto transport trailers and the towing vehicles required for hauling them can be expensive, potentially increasing transportation costs compared to other solutions.

Loading and unloading time: Depending on the design of the car carrier and the number of vehicles being transported, loading and unloading processes can be time-consuming, and require specialized knowledge and skills.

Limited use: Car carriers are designed for a specific purpose, transporting vehicles, and are therefore not suitable for various other types of cargo commonly carried by more versatile trailers.

In conclusion, car carrier (auto transport) trailers provide an efficient solution for transporting vehicles, offering significant advantages in terms of safety, vehicle preservation, and transportation capacity. However, they do have some drawbacks, including limited versatility for other cargo types and challenges related to their size and maneuverability.

Double Drop (RGN) Trailers

What is Double Drop (RGN) Trailers?

A Double Drop (RGN) Trailer, also known as a Removable Gooseneck Trailer, is a specialized type of trailer designed for hauling oversized and heavy cargo. These trailers have a detachable gooseneck, allowing the front of the trailer to be lowered to the ground to create a loading ramp. The trailer features a well or a lower deck height between the front and rear axles, which assists in accommodating taller and heavier loads.

Advantages of Double Drop (RGN) Trailers:

Versatility: RGN trailers are designed to handle a wide variety of oversized and heavy cargo loads, such as construction machinery, industrial equipment, and unique or non-standard items.

Easy Loading and Unloading: The removable gooseneck facilitates simple loading and unloading by allowing the cargo to be driven or rolled on and off the trailer.

Increased Deck Space: The lower deck height of an RGN trailer increases the cargo clearance, making it suitable for transporting tall cargo loads.

Higher Load Capacities: RGN trailers often have higher load capacities, allowing them to carry some of the heaviest cargo loads in the industry.

Disadvantages of Double Drop (RGN) Trailers:

Higher Cost: RGN trailers are generally more expensive than other trailers due to their specialized design and engineering, making them a more significant investment.

Limited Use: The unique design of RGN trailers makes them less versatile when transporting smaller or more standard-sized loads, limiting their use compared to other trailer types.

Complexity: The removable gooseneck adds an extra layer of complexity to the trailer. Operators must be familiar with detaching and reattaching the gooseneck while ensuring its proper connection and securement for safe transportation.

Limited Availability: Due to their specialized nature, RGN trailers may be less readily available in certain areas, and sharing resources among other companies or renting could be more challenging.

Conclusion

"Ten Common Trailers Compared" provides a comprehensive overview of various trailer types, illuminating their unique features, advantages, and disadvantages. With this thorough comparison, you can make an informed decision about the best trailer for your specific cargo hauling requirements. As the transportation industry continues to evolve, understanding the capabilities and limitations of different types of trailers has become critical to ensuring efficient and safe cargo transportation. Youcan Trailer provides industry professionals with valuable guidance to help them navigate the complex map of trailer options and equips them with the knowledge to efficiently and cost-effectively select a trailer that meets their needs.

WhatsApp

WhatsApp

sales@youcantrailer.com

sales@youcantrailer.com

+8615203709888

+8615203709888