Youcan 3 Axle 40 FT Flatbed Semi Trailer is a versatile and heavy-duty transportation solution designed to handle a wide range of cargo, including containers, building materials, machinery, and other bulky items. It is a popular choice among transporters and logistics companies due to its flexibility, durability, and overall performance.

What is 3 Axle 40 FT Flatbed Semi Trailer?

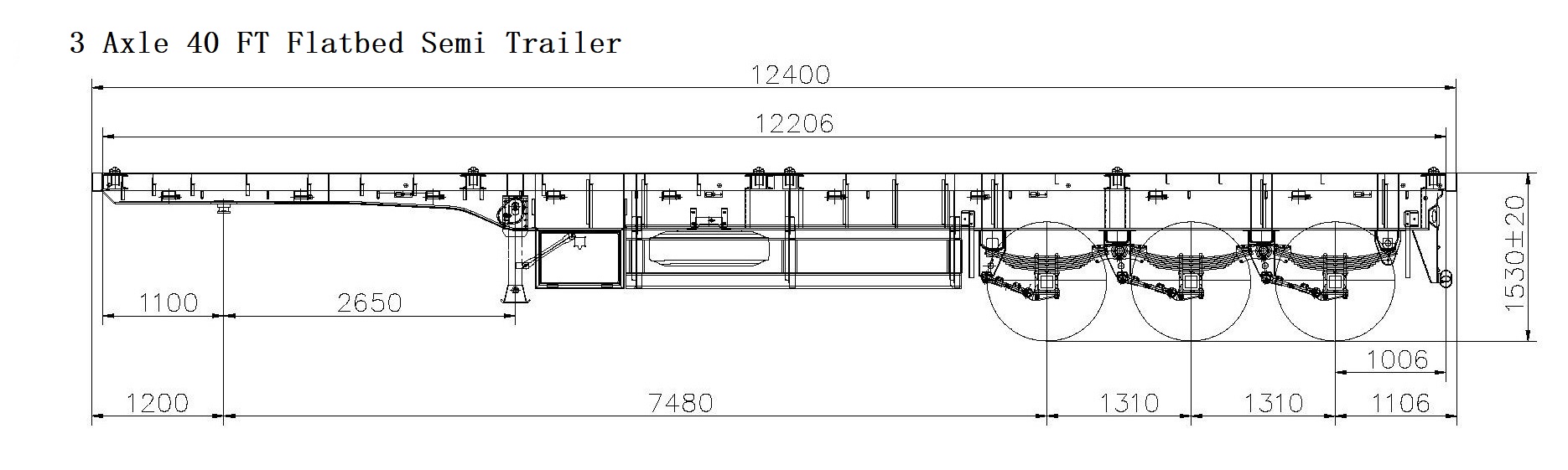

A 3 Axle 40 FT Flatbed Semi Trailer is a type of heavy-duty trailer designed for transporting diverse cargo, including containers, building materials, machinery, and other large items. It consists of a 40-feet long flatbed with an open design and three axles, which assist in distributing the load weight more evenly and providing better stability and handling compared to a two-axle trailer. These trailers are popular in transport and logistics companies due to their flexibility, durability, and overall performance.

Key features of a 3 Axle 40 FT Flatbed Semi Trailer include strong and durable construction, container locks for secure transportation of standard shipping containers, flexible cargo space to accommodate various types of cargo, easy loading and unloading, advanced braking and suspension systems, and customization options to meet specific requirements.

Features of 3 Axle 40 FT Flatbed Semi Trailer

Strong and Durable Structure: The 3 Axle 40 FT Flatbed Semi Trailer's frame is generally made from high-quality steel, providing excellent strength and durability to withstand heavy loads and challenging road conditions.

Three Axles: Equipped with three axles, the trailer offers higher load capacity and better weight distribution compared to its two-axle counterparts, ensuring improved stability, safety, and maneuverability during transit.

Container Locks: The flatbed semi-trailer comes with container locks, allowing for the secure transportation of standard shipping containers (such as 20 ft or 40 ft containers) without requiring additional fastening equipment.

Flexible Cargo Space: The 40 FT length and open design of the flatbed semi-trailer offer ample cargo space and flexibility, allowing for the transportation of various types of cargo, including those with irregular shapes and dimensions.

Loading and Unloading Convenience: The open and accessible design of the flatbed trailer simplifies the loading and unloading process, making it faster and more efficient when compared to enclosed trailers.

Braking and Suspension Systems: The 3 Axle 40 FT Flatbed Semi Trailer typically features advanced braking and suspension systems, ensuring better control, stability, and safety during transportation.

Customization Options: Flatbed semi-trailers can be customized to meet specific requirements, such as additional side rails, covers, or extra lashing points, according to the customer's needs.

Applications of 3 Axle 40 FT Flatbed Semi Trailer

The 3 Axle 40 FT Flatbed Semi Trailer is widely used in a range of industries and applications, such as:

Container Transportation:

The trailer is designed to accommodate standard shipping containers, making it an ideal choice for transporting goods across long distances by road, rail, or sea.

Construction:

Flatbed semi-trailers are commonly used to transport construction materials, such as steel girders, concrete slabs, bricks, and other bulky items.

Machinery and Equipment:

The open design and large cargo space of the flatbed trailer make it suitable for transporting oversized machinery and equipment, such as construction vehicles, agricultural machinery, and industrial equipment.

Logistics:

Logistics companies frequently use flatbed semi-trailers for various transportation needs due to their versatility, adaptability, and ease of loading and unloading.

How to purchase 3 Axle 40 FT Flatbed Semi Trailer?

To purchase a 3 Axle 40 FT Flatbed Semi Trailer, follow these steps:

Research: Start by researching manufacturers and suppliers that specialize in producing flatbed semi-trailers. Browse through their websites and product catalogs to get an overview of their product ranges, quality standards, and pricing.

Compare: Compare different manufacturers and suppliers based on factors such as the trailer's design, build quality, materials used, features, customization options, and price. Consider reading customer reviews and testimonials to get an idea of their reliability and user satisfaction.

Identify your requirements: Make a list of your specific requirements, such as the intended use of the trailer, payload capacity, any particular customization options (like extra lashing points or side rails), your budget, and any other preferences you may have.

Contact suppliers: Reach out to the shortlisted manufacturers or suppliers, either via their websites, email, or phone. Discuss your requirements and preferences with their sales representatives and ask for quotes on the trailers that meet your criteria. Inquire about any additional services they might offer, such as after-sales support, warranties, and shipping.

Evaluate quotes: Evaluate and compare the quotes received based on factors like price, quality, features, and customization options provided. Also, consider the supplier's reputation, customer service, after-sales support, and warranty policies.

Make a decision: Based on all the information gathered, select the supplier that offers the best deal in terms of product quality, features, price, and overall customer service.

Place the order: Once you have chosen a supplier, proceed with the ordering process by submitting a purchase order or a signed agreement. Provide all the necessary details pertaining to your requirements, preferences, shipping address, and payment terms.

Arrange payment: As per the payment terms agreed upon with the supplier, make the required advance or full payment.

Shipping and delivery: Coordinate with the supplier to ensure the timely shipping and delivery of the trailer. Stay in touch with them to monitor the progress of the shipping process.

Inspect and test: Upon receiving the trailer, conduct a thorough inspection for any visible defects or damages, and subsequently, test the trailer's functionality. If any issues arise, contact the supplier straight away to discuss possible solutions or resolve the matter accordingly.

By following these steps, you can ensure a smooth purchasing process for a 3 Axle 40 FT Flatbed Semi Trailer that meets your requirements and expectations.

Price of 3 Axle 40 FT Flatbed Semi Trailers

The price of a 3 Axle 40 FT Flatbed Semi Trailer can vary significantly depending on factors such as the manufacturer, materials used, specific features, customization options, and the region where the trailer is being purchased. As a result, it's challenging to give an exact price range.

However, as a rough estimate, the price of a 3 Axle 40 FT Flatbed Semi Trailer may range anywhere between8000 and 25,000 (USD) worldwide. Trailers manufactured in China or other lower-cost production countries tend to be more affordable, while those built in the United States or European countries are generally priced higher due to higher production costs and more advanced features.

To get accurate pricing information tailored to your specific requirements, it's best to contact manufacturers or suppliers directly, as they can provide detailed quotes based on factors such as the model in question, any additional options or customizations, and applicable taxes, shipping, and after-sale services.

Make sure to obtain multiple quotes from different suppliers to compare prices, product quality, features, and overall value, to help you make a well-informed decision when purchasing a 3 Axle 40 FT Flatbed Semi Trailer.

Suppliers of 3 Axle 40 FT Flatbed Semi Trailers

There are numerous suppliers and manufacturers of 3 Axle 40 FT Flatbed Semi Trailers worldwide. To locate the right supplier for your needs, consider your specific requirements and location, and then research the most suitable options. Youcantrailer is a professional 3 Axle 40 FT Flatbed Semi Trailers manufacturer with 25 year-experience in providing high quality and durable 3 Axle 40 FT Flatbed Semi Trailers for Tanzania, Mozambique, Malawi, Zimbabwe, Zambia, Mali, Ghana, Nigeria, Namibia, Congo, Guinea, Guyana, Senegal, Dominican, Costa Rica, Jamaica, Russia, Mexico, etc

WhatsApp

WhatsApp

sales@youcantrailer.com

sales@youcantrailer.com

+8615203709888

+8615203709888